Research Activities

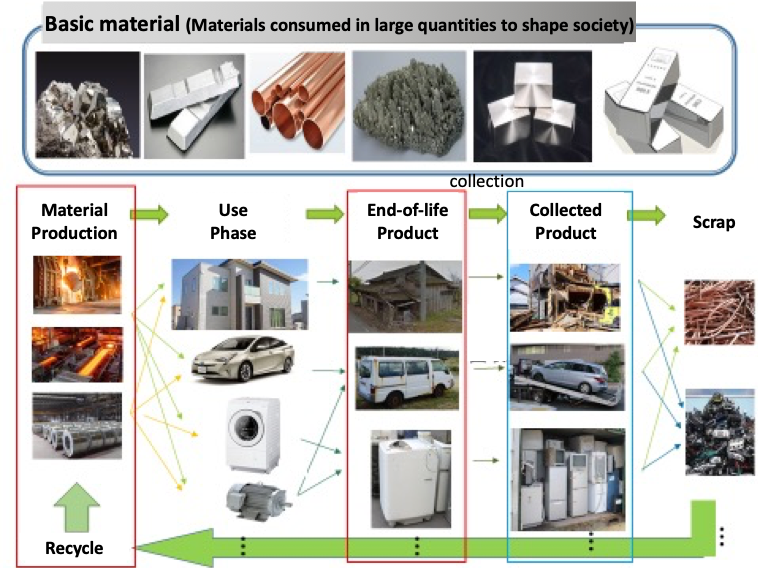

In recent years, the rapid economic development of the world as a whole, including emerging economies, has brought to the fore issues such as environmental and energy problems such as global warming, concerns about the depletion or shortage of raw material resources due to massive consumption of basic materials (iron, aluminum, copper, magnesium, etc.) worldwide, and nationalism (export restraint) of resource-rich countries in response to these problems. In the future, the basic materials industry is expected to face such challenges.

In the end, the basic materials industry will require advanced management that looks at these multiple issues and demands and simultaneously responds to each of them in anticipation of the future. In particular, establishing a "resource-recycling society" is the direction to simultaneously solve resource problems, which are inextricably linked to environmental issues. To establish an efficient resource-recycling society, engineering research is needed to identify several issues and develop analytical methods for conducting precise assessments from a life cycle perspective, including the development, production, disposal, energy consumption, and recycling of basic materials. Based on this background, our laboratory has developed life cycle assessment (LCA) and material flow analysis (MFA) as methods for analyzing and assessing global environmental and resource issues through life cycle analysis of production, consumption, disposal, and recycling of basic materials such as iron and steel materials. We have developed various analytical tools based on life cycle assessment (LCA) and material flow analysis (MFA). Based on the method of material flow analysis for each type of primary material (for example, each detailed classification of metals by alloy), considering the restriction of impurity elements after recycling, we conduct research on engineering analysis and evaluation methods to find a direction to optimize resource recycling in cooperation with industry and the economy, and conduct research. Based on the results, we aim to advise the industry and disseminate information such as policy proposals.

We are working on the following four main research themes.

- Material flow analysis (MFA) for recycling basic materials

- Elucidation of contamination pathways of impurity elements during recycling and future prediction of their concentration

- Development of LCA analysis method considering recycling of metallic materials

- Future prediction of the sustainability (criticality: supply stability) of the use of basic materials in the transition to a decarbonized society.

To advance these four research themes, it is necessary to combine knowledge of materials engineering, theories such as probability and statistics, mathematical model engineering, and thermodynamics. We will propose the results of our research to the government and industry and set future directions for the use of basic materials to realize the sustainable use of metallic materials and the establishment of a framework for a resource-recycling society.

Material Flow Analysis (MFA) Considering Recycling of Basic Materials

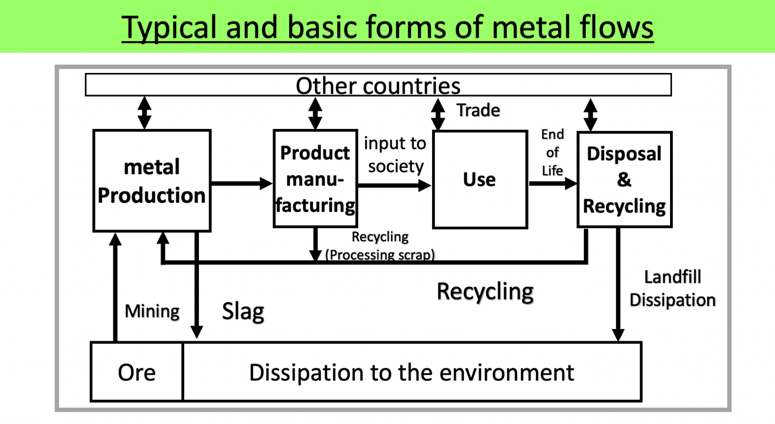

Material flow analysis (MFA) is a method for quantitatively analyzing the flow of materials (input, discharge, and circulation) within a certain period within a coherent "system" (country, region, company, etc.). The amount of materials input into the system, the number of materials discharged out of the system, and the number of materials circulated and utilized is all monitored.

To build a recycling-oriented society, it is necessary to capture the input of resources to the target area quantitatively and the flow of products, waste, etc., produced from them, and to build an optimal flow of material use while understanding the flow of recycling. To analyze the relationship between large volumes of goods, the economy and society, and environmental and resource-energy issues, it is essential to quantitatively capture the flow of materials and energy among economic entities, and material flow analysis is the "compass" for a recycling-oriented society as a method for this purpose. In recent years, with the growing importance of integrated environmental and economic analysis, material flow is again attracting attention along with LCA methods as an information base for developing indicators of sustainable development. It is genuinely an entire research field for realizing a sustainable society.

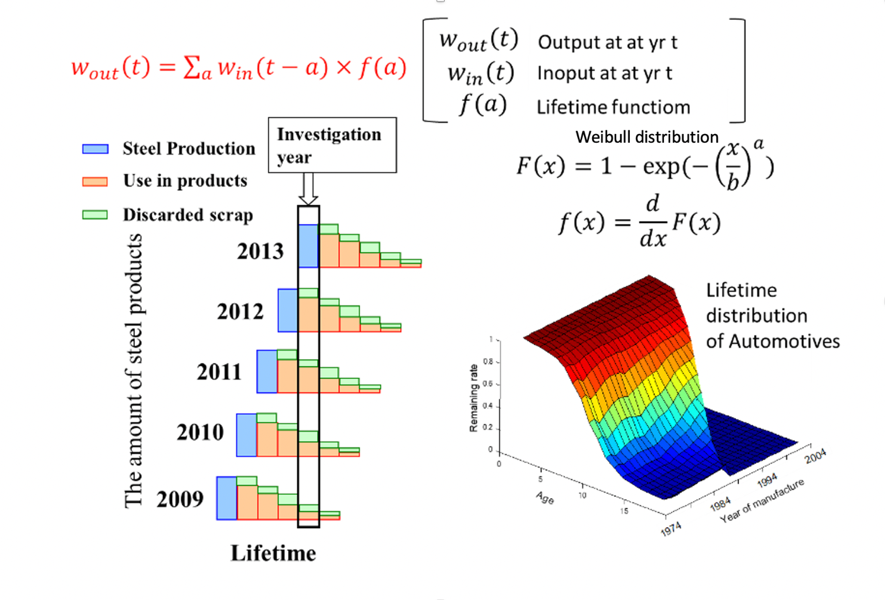

For example, based on a method for estimating and creating explicit material flows for each alloy, including all flows when the material under study is recycled, we will analyze specific metals (mainly steel materials, but also nonferrous metals and other basic materials) in a case study manner using research and development of mathematical models and analytical methods, and develop an analytical model that can be used to estimate material flows for each type of material. We have confirmed that the analytical models we have developed are applicable regardless of the kind of material.

In addition, by applying the Markov chain model to the material flow of steel materials in Japan, we developed an indicator and its derivation method to comprehensively evaluate factors such as end-of-life product recovery rate, product life distribution, and steelmaking yield. We confirmed that our methodology applies to base materials in general, such as copper and aluminum materials.

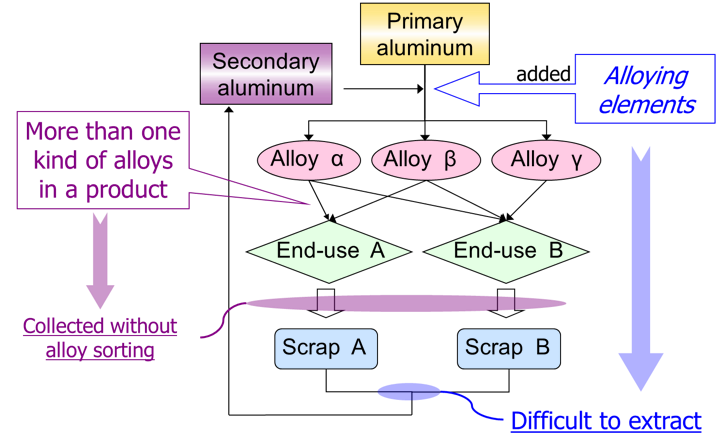

Material flow, including a scrap of rolled aluminum, was analyzed to determine the optimal scrap flow in terms of impurity elements. In the aluminum alloy flow, silicon, iron, and copper are constraints for recycling from sashes to 3000 series. Still, the results suggest that aluminum cans mixed with end tab material with fewer constraint elements and dilution of new bullion cans can be recycled in the same way.

Elucidation of the pathways of contamination of impurity elements during recycling and future prediction of enrichment

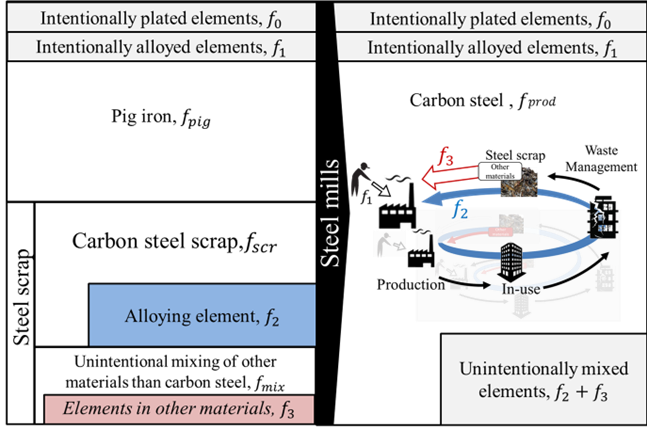

The biggest challenge in promoting the recycling of base metals is how to prevent the mixing of impurities with other materials during scrap metal recovery from used products, which is inevitable.

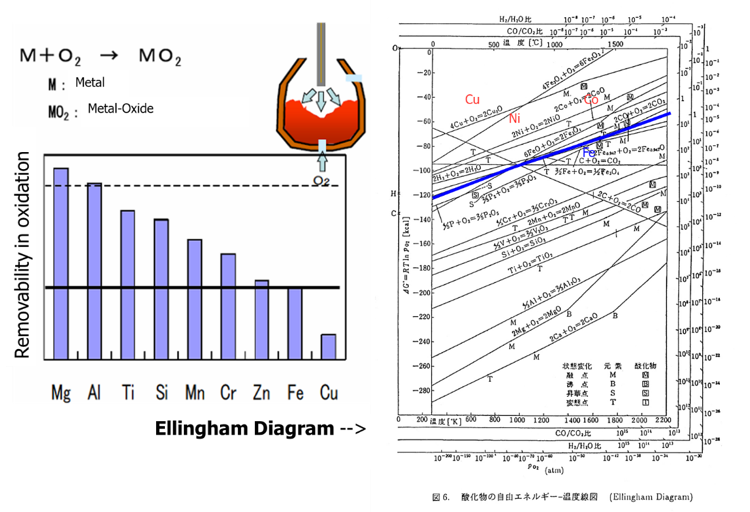

In the case of metals, unintended impurities can become a contamination factor if other materials and alloys are not adequately separated at the time of scrap recovery. Among these contaminants, elements that cannot be separated in the remelting process once mixed in may gradually become concentrated after repeated recycling. This will degrade the quality of the base metal and eventually lead to the loss of the material in the recycling process.

A sustainable resource-recycling society will not be established due to the limited number of uses for which the material can be reused.

This laboratory is researching methods to predict when recycling restrictions may occur using mathematical models. They are also analyzing and clarifying, from an engineering perspective, the routes by which such impurity elements are introduced, what parts of the material flow need to be changed, and what technologies need to be developed by what time to achieve sustainable recycling society.

Development of LCA Analysis Methodology Considering Recycling of Metallic Materials

After conducting the detailed material flow analysis described above, the environmental impact (especially CO2 emissions) is quantitatively evaluated from the material’s life cycle viewpoint.

In LCA, we established a method for deriving the end-of-life recycling rate (EoL-RR) as data necessary for inventory analysis of circulating materials and a generalized LCI evaluation method that considers the recycling of metal materials.

Future projection of sustainability (criticality: security of supply) of the use of basic materials through the transition to a decarbonized society

Achieving a decarbonized society will require energy conversion, including energy conservation. A significant shift in products and metals (copper, nickel, cobalt, etc.) essential for renewable energy power generation and electric vehicle manufacturing, which are expected to expand in the future, are expected to see a significant increase in demand worldwide and may become difficult to obtain (supply shortages). Japan may have to import metal resources from outside Japan. Japan will have to rely on imports from outside of Japan to procure metal resources, and it will be necessary to stably secure mineral resources to meet the increasing demand. To stably certain mineral resources, it is essential to formulate procurement strategies that match the supply risk of individual metals. For this reason, we are researching risk assessment methods for metal resources.